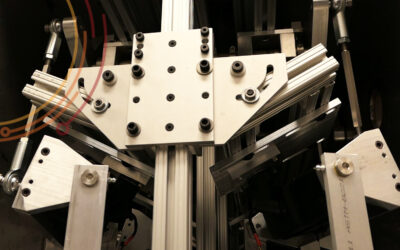

We recently worked with one of our automotive customers to upgrade two of their door handle cycling test stands. These stands are used to simulate a person opening a car door thousands of times in various environmental conditions.

The stands were operated with basic PLCs and had no data acquisition or failure detection capabilities. Modern automobiles have much more complicated door handles, incorporating lights, motors, cameras, etc. which all have to be tested to strict OEM requirements.

SIS was able to upgrade the existing test stands by adding data acquisition and control systems to operate and verify the correct operation of the various new door handle capabilities. The PLC was removed and replaced with a LabVIEW system which greatly expands the operator interface, test stand ease of use, detects any failures as soon as they occur, and provides logged data so that engineers can determine how the door handles operated and make informed decisions.